comma CMMS equipment maintenance blog

What is a CMMS and what you need to consider to make it work for you?

Published 2023-11-04 by Rui J Alves (a 12.3 minute read) | Back to the main page

Introduction

A Computerized Maintenance Management System (CMMS) is, in very general terms, a software tool that helps organizations manage their assets and equipment. In short, these systems can help improve operational efficiency, reduce maintenance costs, increase asset lifespan, and ensure compliance with safety and environmental standards and thus please owners, managers, regulators and guests or clients — one of those rare cases where everyone wins! In this article, I will address what a CMMS is (along with a little history) and analyze the different CMMS types along with advantages and disadvantages of each. Like an angel on earth, making sure I do the work, so you don’t have to, I also address some important considerations you need to consider to increase the odds of a successful CMMS implementation on your organization, which in the end, is all that matters.

Some History

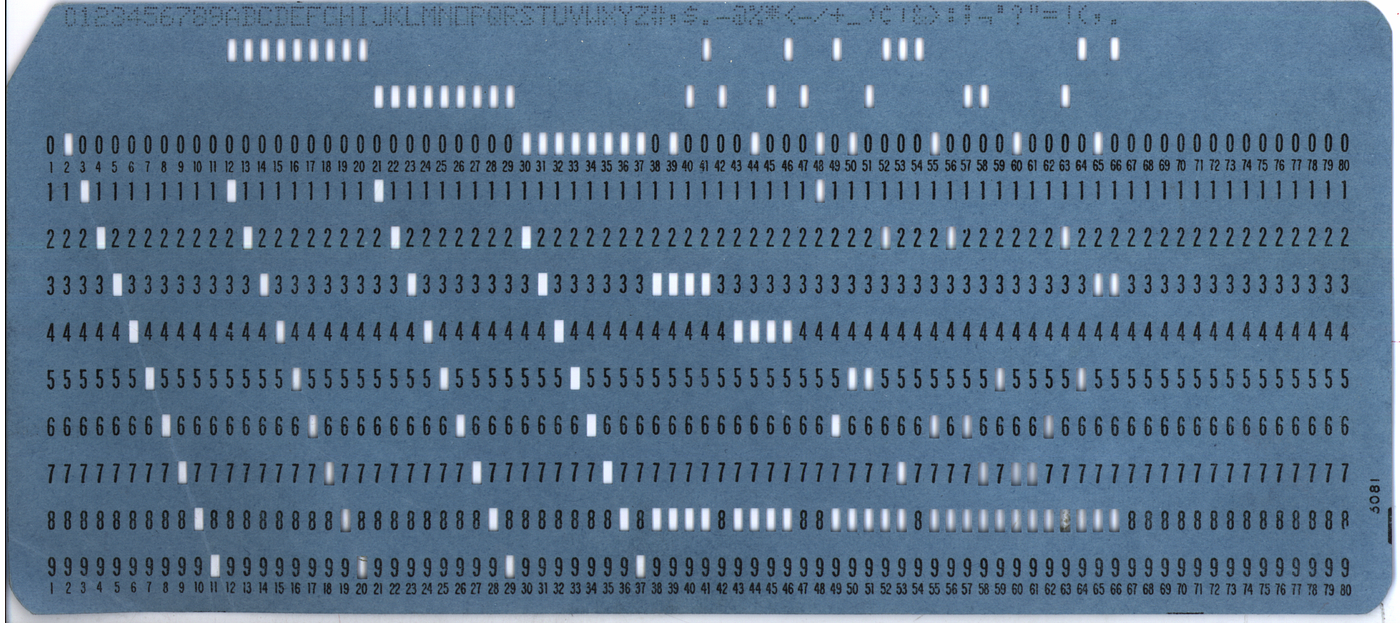

CMMS solutions have been in use for many years (since the 60s, as far as I can tell) in industries from aviation to utilities where the safety and capital-intensive requirements impose an absolute demand on the efficiency and proper rigorous management of maintenance procedures and costs.

The high costs at the time for both the software solutions themselves and for the IT infrastructure required, kept them far from being a possibility for smaller, less-capital intensive organizations which continued to rely on paper to support their scheduling and logging techniques.

As the costs involved dropped with the evolution of technology, more and more industries jumped in at the point at which the CMMS running costs become lower than the costs of system failures attributable to fully manual input and retrieval of data on physical formats.

Fast forward to the nineties, and the advent of the internet along with cheaper professional-grade computers and servers that gradually allowed more companies to make the jump to a fully dedicated maintenance management software (there was a transactional period where computer-based tools like spreadsheets were used to digitize plans and procedures but that was still a pretty much fully manual input on “digital papers” — better, but not quite there yet).

From the early 2000s onwards CMMS adoption really took off and most companies where equipment plays an important role in the production of whatever it is they create should really be considering using a dedicated maintenance platform (and most companies are).

General CMMS advantages

Now that cost is really not a barrier to entry anymore, other benefits justify the use of a CMMS. Some of those benefits are as follows:

- Automating work orders and preventive maintenance schedules.

- Tracking inventory and spare parts.

- Monitoring asset performance and condition.

- Generating reports and analytics.

- Generating proof of actions for regulatory or insurance purposes.

- Enhancing communication and collaboration among maintenance staff and stakeholders.

- Assessing maintenance costs for both labor and parts. For example, you can compare the maintenance costs of keeping a system operational with another of the same type.

It’s not like some of these parameters could not be traced before with paper of excel sheets, it’s that now a lot more information can be easily logged and meaningfully extracted in almost real-time.

Things to consider when implementing a CMMS

As with anything, however, it’s not all clear blue waters and green beautiful fields with unicorns, there are some aspects to consider, and you may have already been in the middle of some of these:

- Implementing a CMMS is not a simple task. Significant planning and preparation need to be taken into account.

- There’s a lot of competition on this field. I mean A LOT of competition. That can create confusion and make it hard to decide on what tool to select.

- Consider that the effectiveness of a CMMS is closely linked to the effectiveness of existing organizational procedures and culture. You may very well amplify inefficiencies rather than optimizing your workflows. You buy into the dream and get a nightmare instead.

Points to pay attention to

To address the not so good points listed above (and others) and in order to increase the odds of a successful CMMS implementation, proper time and attention should be given to the following points (it’s pretty much common sense but sometimes you need to read it from someone else):

- Conduct a thorough assessment of the current maintenance processes, workflows and practices (are you going to increase inefficiencies?).

- Clearly define the scope, objectives and expectations of all staff involved.

- Select a suitable CMMS vendor and software solution (more on CMMS solution types down below).

- Secure the necessary resources, budget, and support from all involved from technicians all the way to top management (by the way, if top management doesn’t care, nobody will either).

- Develop a detailed implementation plan and timeline and work closely with the vendor to assess the viability of your vision.

- Train users.

- Evaluate the results and make adjustments as needed.

- Depending on the size of the organization, consider the creation of a task force comprised of a representative of each professional category involved but ensure there is a task force head that can manage everyone’s inputs without getting bogged down in endless discussions.

CMMS types and why they’re good. Also, why they could be bad.

At this point, I feel like it is relevant to quickly go through the major variants of CMMS types out there along with advantages and drawbacks of each so you can see what is it that makes sense to your particular setup — this is definitely not a one-size fits all kind of thing.

Number 1: This one is in the cloud (AKA Cloud-based CMMS).

This type of solution is hosted on a remote server and is accessed via the internet. Someone else owns and takes care of the IT infrastructure. That someone also gets all the headaches of service level agreements, actual hardware maintenance and more IT related aspects in order to keep customers happy (and connected 99.9% of the time).

Why would you want this type of solution? Well, read on:

- It is accessible from any device with an internet connection, which allows for more flexibility and mobility for the maintenance staff and managers. More flexibility is always a plus.

- It is easier to install, update, and maintain, as the software provider takes care of the technical aspects and provides regular backups and security updates. You’re basically outsourcing IT services. Leave the computer nerds out of your premises and somewhere they can thrive (good for everyone)!

- It is more scalable and adaptable, as the software can be customized to fit the specific needs and requirements of each organization, and the storage capacity can be adjusted as needed. This is true of on-premises software too, I guess.

- This one is important: it is more cost-effective, as the software is paid for on a subscription basis, which eliminates the upfront costs of hardware, licenses, and installation, and reduces the ongoing costs of maintenance and upgrades. Plus unsubscribe at any time should the service level not be what you expect or something (yes, you may have put in a lot of work but you’re never really, really stuck).

I’m here to give you all perspectives and, even though I am 100% in favor of cloud-based solutions for almost all companies (maybe the pentagon should be more careful than most), there are, of course, some things that are not so great:

- You’re dependent on an internet connection. But then again, you’re dependent on the power company too.

- You IT security requirements may not be fulfilled by the vendor (again, think the Pentagon).

- You rely on the existence of the supplier (pay them well so they don’t go down! But seriously, it is a risk).

- It is more vulnerable to cyberattacks.

Number 2: On-premises CMMS (it’s all yours, includes a lot of headaches)

This type of CMMS software is installed in the company’s own servers and computers. If you build washing machines, you may not want to have to deal with all that, just saying — keep focused on the core business. Anyway, I believe I owe you a list of pros and cons for this option too, so here it is for your convenience:

Why it could be a nice thing to have:

- More control over data security and privacy.

- The organization can tailor the CMMS to its specific needs and preferences and integrate it with other existing systems and software (I’m assuming there’s an internal IT department already). The organization can also update and upgrade the CMMS at its own pace and schedule. Full control.

- More independence and stability. Even more control, congratulations.

I think the negatives are pretty obvious though (I know, I’m biased but these may still be able to guide you in some way):

- Consider higher upfront and ongoing costs. Hardware, software, licenses, installation, maintenance — that all costs money. Ah and there’s more: you also bear the costs of electricity, cooling, space, security, etc — but you may have that already actually.

- More complexity and responsibility. You now must handle all the technical aspects of keeping the CMMS running. Configurations, updates, upgrades, backups, recovery, troubleshooting, and bug fixes are all up to you.

- Considerations and risk associated with scalability and flexibility. There is the need to estimate current and future needs for the CMMS and ensure enough hardware and software to meet those needs.

- It may be harder to switch to a different vendor or platform.

In conclusion

A CMMS is now a must, I think we can all more or less agree to that. The good news is that you have many, many options. On the other hand, the bad news is that you have many, many options. It is impossible to go through an article like this and come out with a formula (which is what I would like to provide you with) but the reality is that the parameters that go into your selection are wide-ranging; basically, each case is unique. I’d say that for the majority of small to medium sized companies, a cloud-based solution is the best. What I know happens too, is that companies will kind of follow a path that is common to others in the same market. If a partner or even competitor is using a CMMS package, the likelihood is that your company will investigate the applicability of that package to your operations. Technically speaking if it works for them, it probably works for you (note disclaimer on the current organizational culture — it may fail not because of the tool itself).

I hope that this little shallow dive onto the world of CMMS solutions was of value to you. As with many other things, just start, think a little and mostly act.

If you found any value on this text, I’d appreciate you’d share it with your network. I write about technological tools and concepts applied to industrial asset maintenance management for a wide range of industries. See my account here on medium.com or on our blog for more like this.