The steps for the calibration of tools (e.g. torque wrench) or equipment (variable power supply or multimeter) are similar and described on the next text:

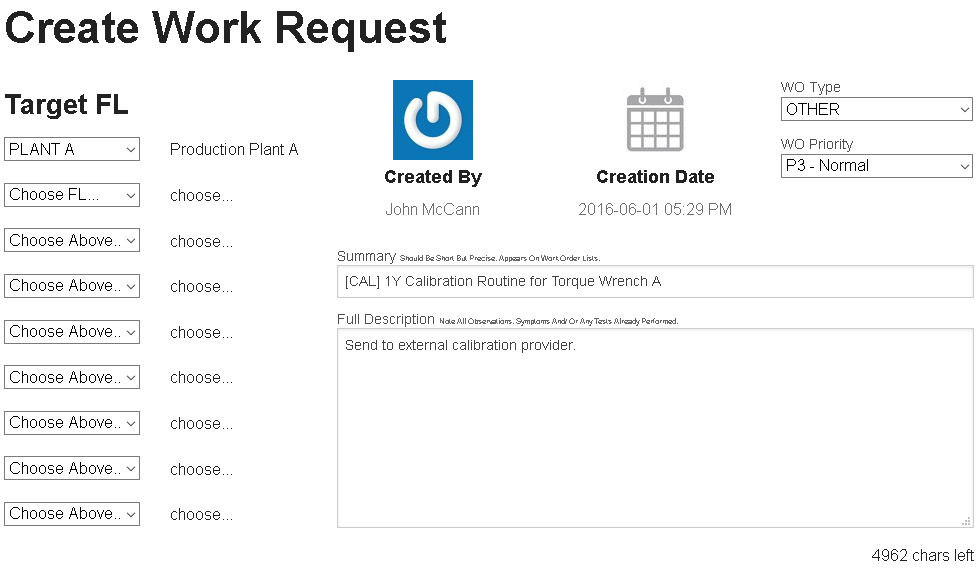

Create a maintenance plan source WO for the calibration of the tool by creating a work request.

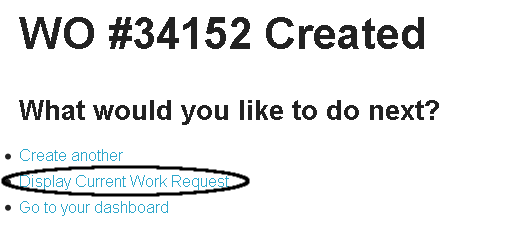

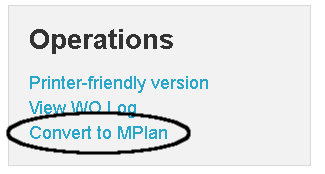

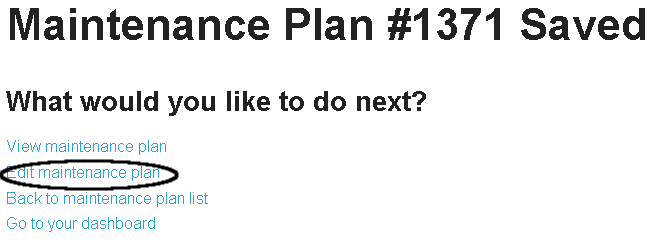

Re-enter the work request you created above in edit mode and click the “Convert to MPlan” link on the bottom left.

Re-enter the work request you created above in edit mode and click the “Convert to MPlan” link on the bottom left.

|

|

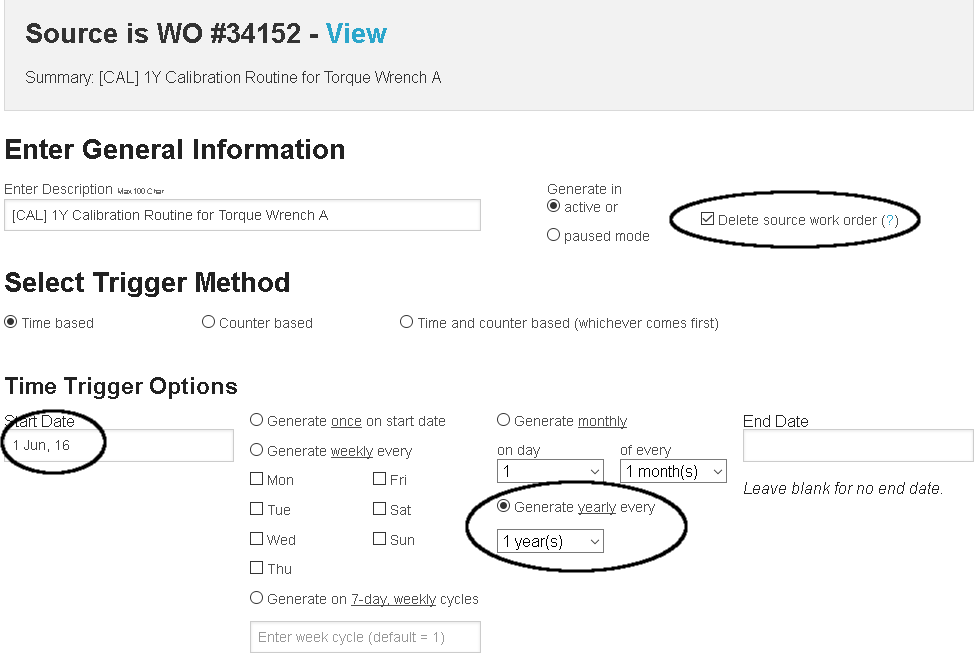

On the create maintenance plan screen, set this as a “time based” plan (this is the default option) and set the start date and the frequency at which the job should come out (1 year on this example). Ensure the “Delete source work order” option is checked as we have done this source work order solely with the purpose of creating a maintenance plan and there’s no need to keep this source active on the system. Click the “Create Maintenance Plan” button at the bottom.

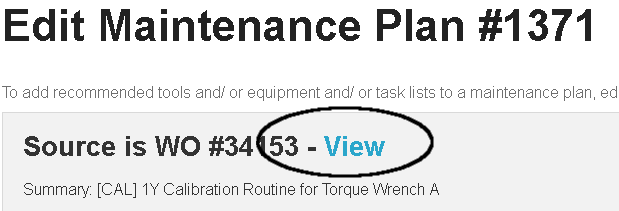

It is possible to leave this task like this. After all, the work order is going to be issued regularly in 1-year intervals to do this job. We can however make things a little more organized by linking the actual tool to be calibrated to the source WO and have that come out automatically each time. To link the tool, go back to the maintenance plan in edit mode and then click the “View” link to open the source work order in edit mode (will open on another tab).

|

|

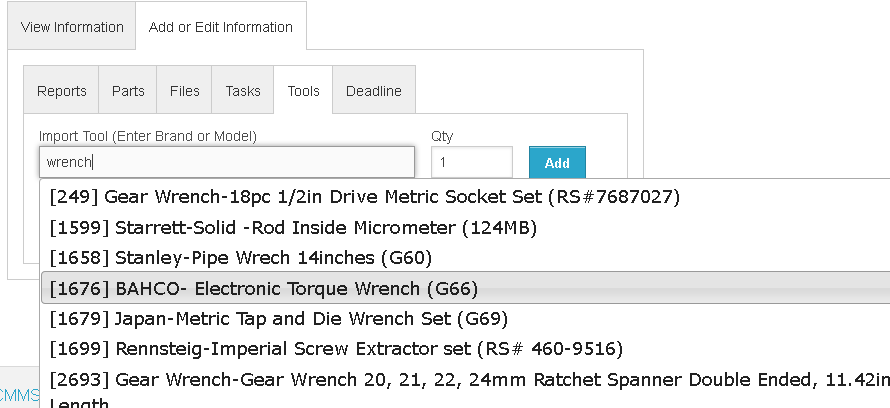

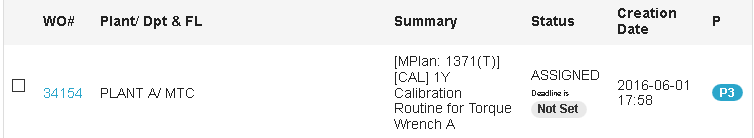

FOR TOOLS: Go to the “Tools” sub-tab on the “Add or Edit Information” tab and write the first few characters of the tool to calibrate (in this case an electronic torque wrench). Click the “Add” button to add this tool to the list needed by this work order and save the work order. This tab can now be closed.

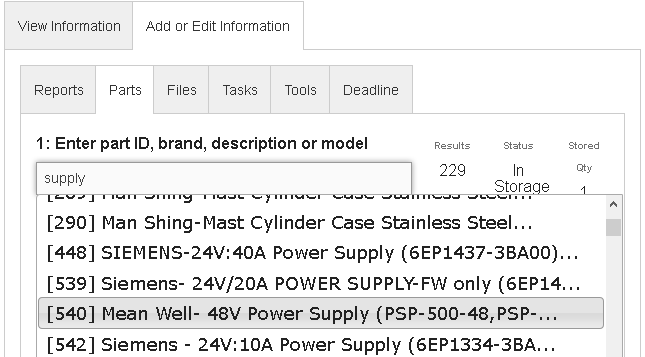

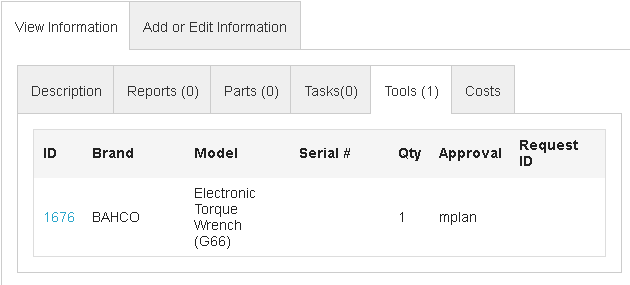

FOR EQUIPMENT: Go to the “Parts” sub-tab on the “Add or Edit Information” tab and write the first few characters of the equipment to calibrate (in this case a 48V power suppkye). Click the “Add” button to add this item to the list needed by this work order and save the work order. This tab can now be closed.

Go to the maintenance plan search console to confirm the maintenance plan was created successfully.

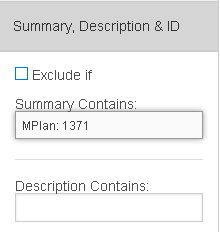

To check the calibration history of the tool in question, it is only necessary to filter the maintenance plan on the work order search console (in this case “MPlan 1371”). All work orders issued by that maintenance plan will be listed, effectively giving the calibration history of the tool.

|

|

FOR TOOLS: Opening each work order will also show the tool to be calibrated for extra control.

It is also possible to add several tools to the maintenance plan source work order to calibrate a group of tools instead of having one work order for each tool to be calibrated.

FOR EQUIPMENT: Opening each work order will also show the equipment to be calibrated for extra control.

It is also possible to add several equipment items to the maintenance plan source work order to calibrate a group of equipment instead of having one work order for each item to be calibrated.

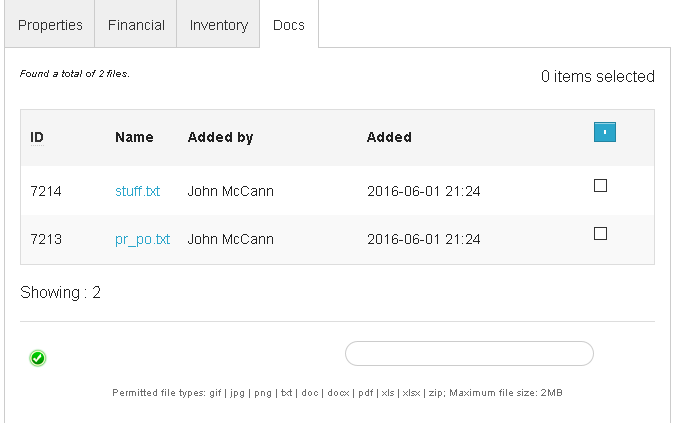

For equipment and tools, it is possible to keep a record of the calibration certificates by linking those documents either to the equipment or tool page (preferable) or to the work order used to trigger the calibration service.

comma CMMS

comma CMMS